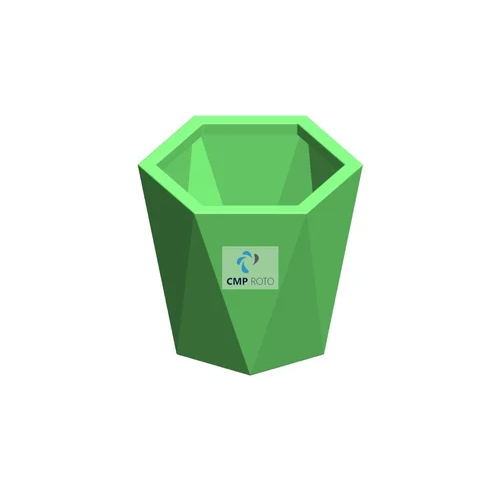

Toys Rotational Mould

200000 INR/Unit

Product Details:

- Mold Base Customizable/Standard as required

- Cavity Single or Multiple based on design

- Molding Material Plastic/Polymer suitable for rotational molding

- Life Span Long Working Life

- Shaping Mode Rotational Molding

- Usage Industrial

- Material High-grade Metal (Steel or Aluminum)

- Click to View more

X

Toys Rotational Mould Price And Quantity

- 1 Unit

- 200000 INR/Unit

- High, suitable for rotational molding

- Children's Outdoor & Indoor Play Equipment

- Smooth/Glossy

- Available for Size, Shape, and Logos

- Precision Machined and Welded

- 3D/2D Modeling Available

- Yes, with Protective Coating

Toys Rotational Mould Product Specifications

- Varies as per design and size

- Single or Multiple based on design

- Toys Rotational Mould

- Plastic/Polymer suitable for rotational molding

- Rotational Molding

- Orange

- Customizable/Standard as required

- Industrial

- 0.1 mm or as specified

- Up to 1 million cycles depending on material

- Long Working Life

- High-grade Metal (Steel or Aluminum)

- 23x18x10 Inch

- High, suitable for rotational molding

- Children's Outdoor & Indoor Play Equipment

- Smooth/Glossy

- Available for Size, Shape, and Logos

- Precision Machined and Welded

- 3D/2D Modeling Available

- Yes, with Protective Coating

Toys Rotational Mould Trade Information

- Cash in Advance (CID)

- Depends on machine setup

- 10 Unit Per Month

- 30 Days

- All India

Product Description

We are one of the leading names for serving Toys Rotational Mould to our customers. It is an important component for making several plastic toys using rotational molding techniques. The finest of aluminum or steel is used in making this mould providing the cavity required for shaping molten plastic into toy forms. It ensures uniform material distribution, leading to consistent product quality and strength. Toys Rotational Mold can accommodate a wide range of toy designs, from simple shapes to complex figures. We strive to deliver this mold within a stipulated time frame.

High-Quality Manufacturing for Reliable Performance

Each Toys Rotational Mould is built using advanced precision machining and welding, resulting in superior durability and a flawless glossy finish. With robust resistance to corrosion and temperature, these moulds maintain integrity even after repeated use, ensuring consistent product quality for industrial clients involved in play equipment manufacturing.

Customization to Meet Your Unique Project Needs

We offer extensive customization options for size, shape, logos, and colors. Clients can choose between single or multiple cavities as required, and both standard and custom mold bases are available. Our team supports 3D/2D modeling, facilitating tailored solutions and making it easy to match specific requirements for childrens play equipment.

FAQs of Toys Rotational Mould:

Q: How is the surface finish of the Toys Rotational Mould achieved?

A: The smooth and glossy surface finish is achieved using precision machining and welding processes, ensuring the final mould produces a high-quality aesthetic on the molded play equipment.Q: What customization options are available for this mould?

A: The mould can be customized for size, shape, cavity arrangement (single or multiple), logos, and colors. Both standard and custom mold bases are available, and design support is provided through 3D/2D modeling.Q: When should I choose a single cavity versus multiple cavities for my application?

A: A single cavity mould is ideal for smaller production runs or complex parts, while multiple cavity moulds increase output and are suitable for high-volume manufacturing needs.Q: Where can these rotational moulds be used?

A: These moulds are specifically designed for producing childrens outdoor and indoor play equipment, but their durability and flexibility mean they can also be used for other industrial rotational molding applications.Q: What is the process for ordering a customized Toys Rotational Mould?

A: Start by discussing your project requirements, including size, shape, and branding needs. Our team provides 3D/2D modeling for approval. Once confirmed, the mould is manufactured to your specifications using high-grade metal and protective coatings.Q: How does the protective coating enhance the moulds lifespan?

A: The protective coating offers excellent resistance to corrosion and high temperatures, significantly extending the moulds operational life, which can reach up to 1 million cycles depending on the material used.Q: What are the main benefits of using this type of mould?

A: Benefits include high customization, durability, precise tolerances, long working life, and consistent product quality, making the mould ideal for demanding industrial and play equipment manufacturing.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Rotational Mould' category

Send Inquiry

Send Inquiry Send SMS

Send SMS